The Intricate World of Diecasting: Precision in Manufacturing

The Intricate World of Diecasting: Precision in Manufacturing

Blog Article

Diecasting is a highly specialized manufacturing technique that converts melting metal into precise components through the use of high-pressure molds. This technique has become indispensable in a variety of industries, such as electronics, aerospace, automotive, and consumer goods, due to its ability to produce complex shapes with exceptional precision and consistency. In combining the principles of metalworking with the latest in engineering it provides unparalleled precision and efficiency, making it the foundation of contemporary manufacturing. This article dives into the complex world of diecasting by studying its processes, benefits and potential applications.

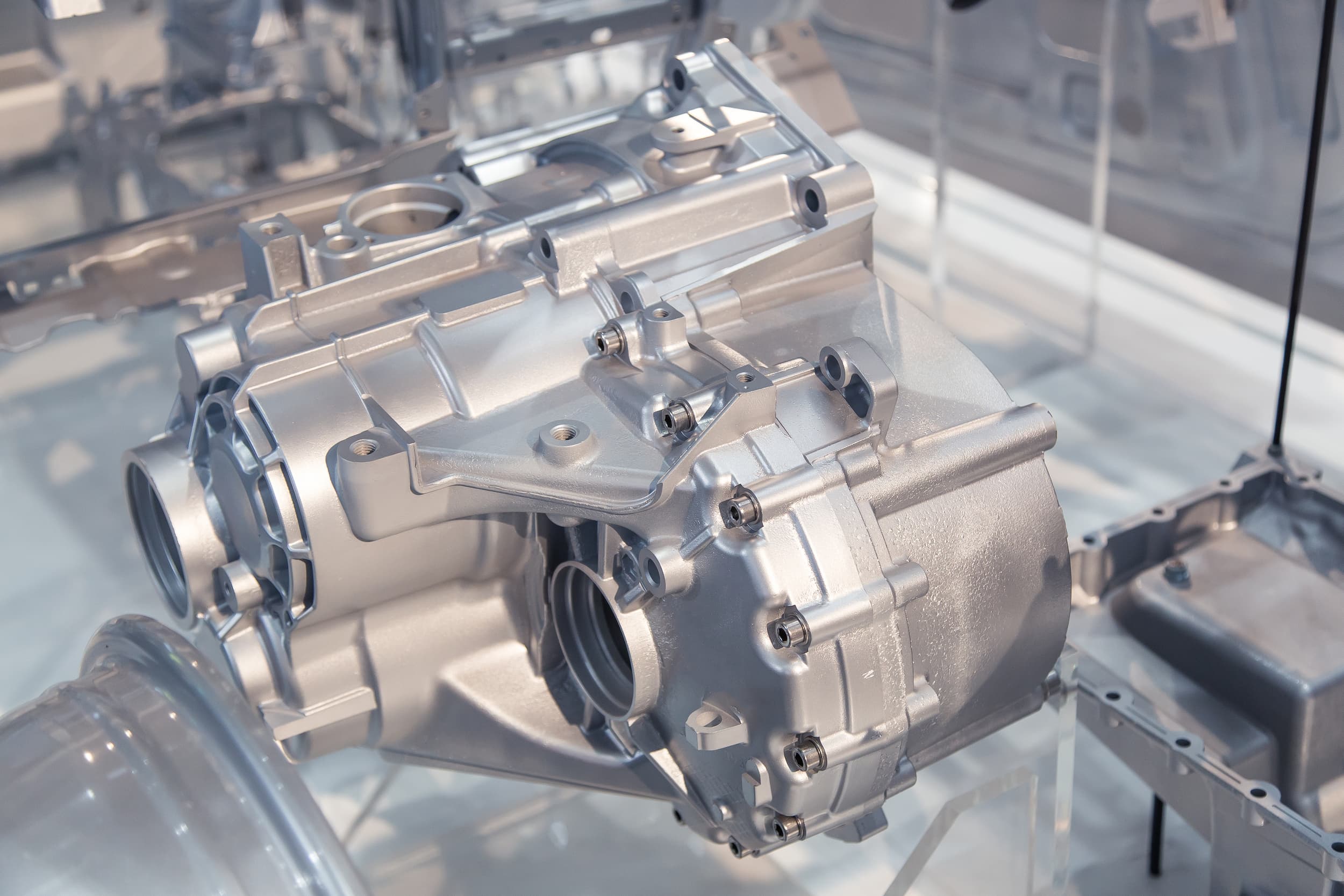

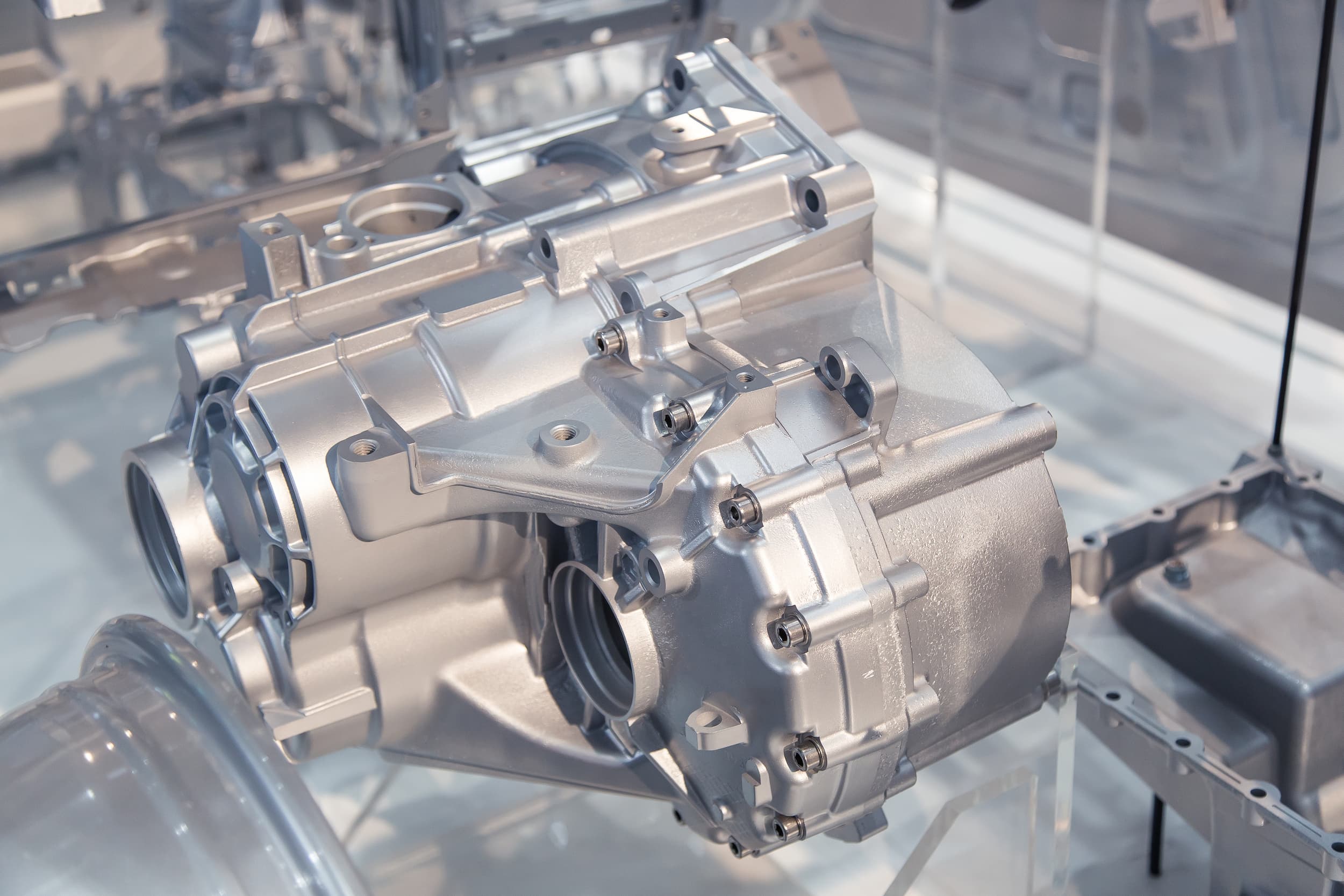

At the heart of diecasting is the mold. It's also known as a"die," which is carefully designed and constructed from hardened steel to withstand the harsh conditions that are encountered during the casting process. The shape of the die is important, as it has to accommodate the melting metal's flow and hardening while making sure that the tolerances are tight to assure high-quality. In the process of diecasting, metals such as zinc, aluminum, magnesium, and copper are heated to melt. The molten metal then gets put into the die cavity with high pressure, and fills every crevice and crevice of the mold. The rapid cooling and finalization of the metal results with parts that show outstanding dimensional precision as well as a perfect surface finish, usually without the need for further machining or finishing processes.

One of the significant advantages of diecasting is its capacity to manufacture parts with high precision in dimensional measurement and smooth surface surfaces. The high-pressure injection ensures that the molten metal is precisely molded to the mold, which results in pieces that require no machining or finishing. This is particularly beneficial when it comes to creating complex geometries or thin-walled segments that are hard or impossible to make by other processes of manufacture. Additionally, diecasting can produce products with high-quality tolerances and excellent repeatability, making it perfect for large-scale production. The efficiency of the process can also result in cost savings because the higher rate of production reduces labor costs and waste material.

Diecasting can also produce parts with superior mechanical properties. The speedy cooling process of liquid metal that is formed during the casting process creates the formation of fine grains, increasing the strength and durability of the final product. Diecast products are appropriate for uses that require high performance and reliability. As an example, in the automotive sector Diecast components are utilized for transmissions, engines, and structural elements, where their weight-to-strength ratio plays a crucial role for vehicle efficiency and safety. Similarly, in the aerospace sector diecast components aid in the development of lighter but strong structures, crucial for optimizing performance and efficiency in fuel consumption. To generate extra details kindly head to Senadiecasting

The versatility of diecasting extends to a wide array of applications. Within the automotive sector diecast parts are found for transmissions, engines and structural parts, contributing to the lighter and fuel efficient vehicles. In the electronics industry, diecasting is employed for the production of heat sinks, housings and connectors. This ensures optimal thermal management and durability. Household appliances, power tools and even toys profit in diecasting's accuracy and efficacy, with parts ranging from knobs and handles to internal mechanisms. The ability of the process to work with different metals as well as its capability to create parts that have intricate design make it suitable for many industries, each profiting from the distinct advantages the process offers.

Diecasting is a highly efficacious and versatile manufacturing process which helps in creating intricate metal components with extreme precision and consistent. Its capability to make components with fine details precise tolerances, perfect tolerances, as well as polished surfaces makes it a valuable tool in a variety of sectors, from automotive to aerospace, to consumer electronics, and even beyond. Utilizing different types of materials also enhances the utility of diecasting, allowing manufacturers to choose the most suitable alloy to suit their requirements. As technology advances and the demand for premium, affordable components increases, diecasting will remain vital within the production process, driving innovation and excellence within the production.